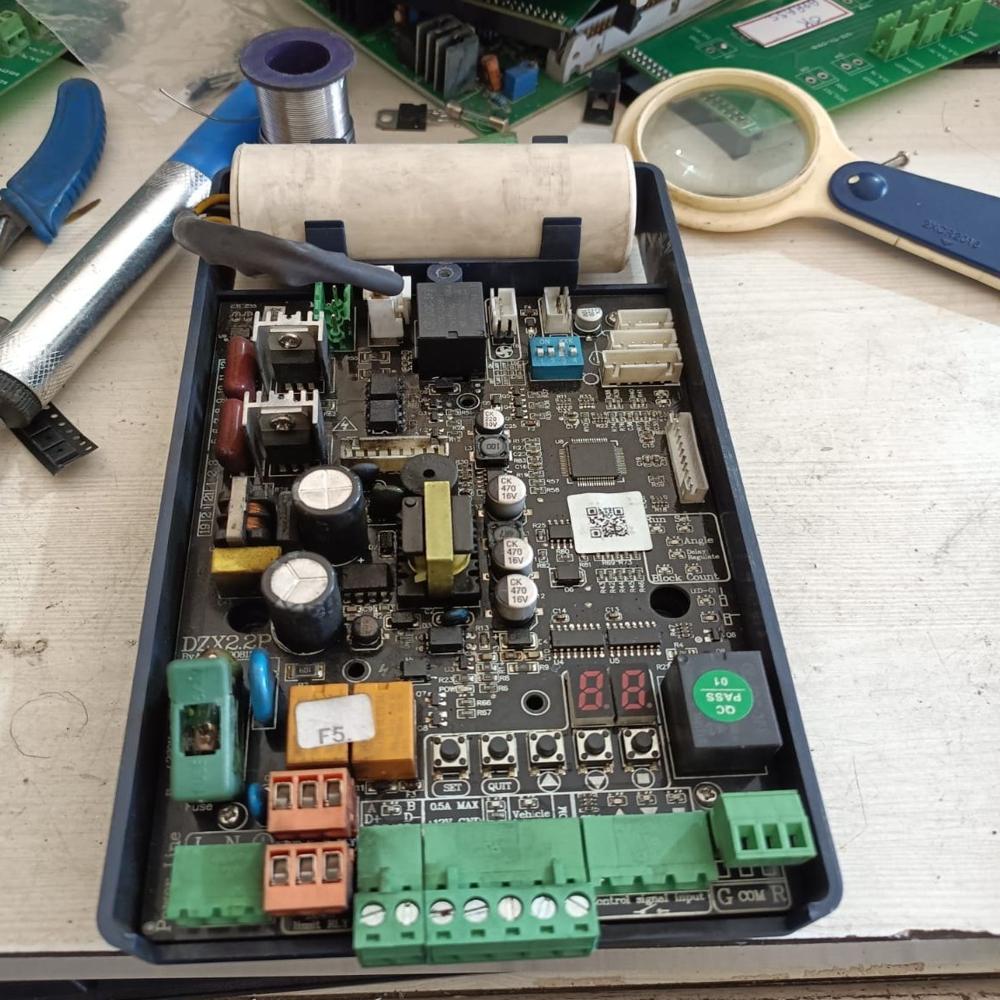

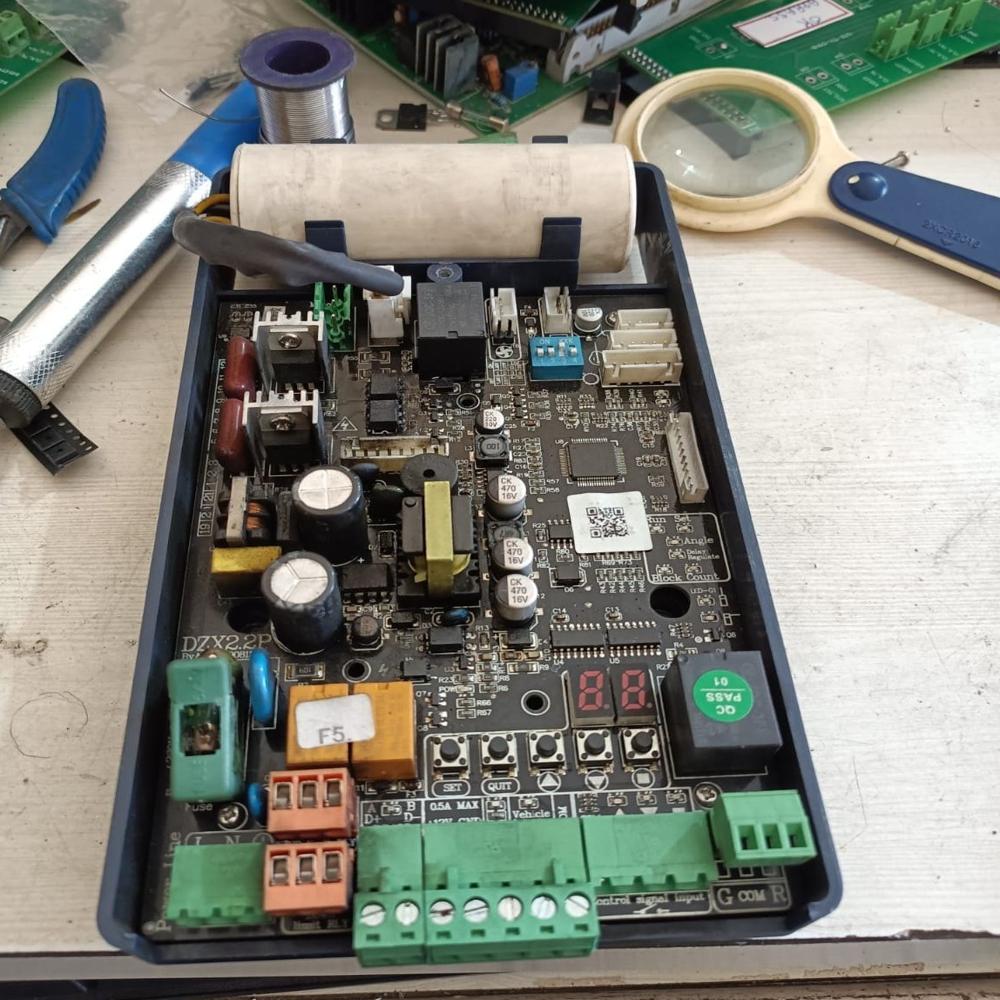

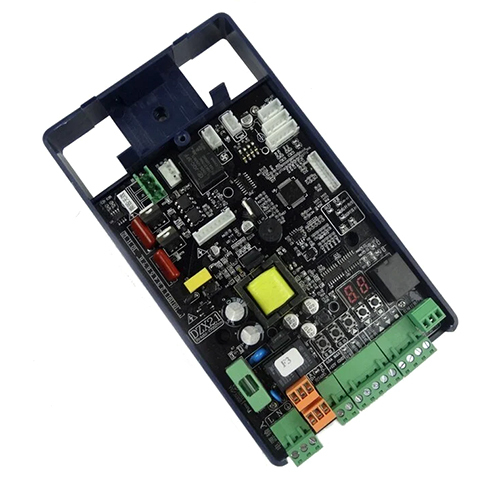

Boom Barrier Controller PCB

Product Details:

- Chip Type 1

- Model No ASRSS106

- I/O Cards Type Barrier Controller PCB

- Condition New

- Compatible Port/Slot 1

- Use Industrial

- OS Supported Yes

- Click to View more

Boom Barrier Controller PCB Price And Quantity

- 9500.0 INR/Unit

- 1 Piece

Boom Barrier Controller PCB Product Specifications

- Yes

- 1

- Yes

- New

- Barrier Controller PCB

- 1

- ASRSS106

- Industrial

Boom Barrier Controller PCB Trade Information

- 1

- Cash in Advance (CID)

- 1 Piece Per Month

- 1 Week

- No

- If order is confirmed we will reimburse the sample cost

- perfect packing

- Asia

- All India

- boom barrier controller pcb

Product Description

A Boom Barrier Controller PCB (Printed Circuit Board) is an essential part of the boom barrier system, controlling the operation of the boom gate. It processes inputs from sensors, remote controls, or access systems, and then manages the electric or hydraulic motor that raises or lowers the boom arm. Here are the basic details of a Boom Barrier Controller PCB:

1. Function of Boom Barrier Controller PCB:

-

Motor Control: The controller sends signals to the motor or actuator to raise or lower the boom arm.

-

Sensor Integration: The PCB processes inputs from sensors that detect the presence of vehicles, obstacles, or the position of the boom arm.

-

Signal Processing: It processes inputs from remote control devices, keypads, or card readers to allow or deny access.

-

Timing Control: The PCB controls the timing for how long the boom arm stays open or closed.

-

Safety Features: It ensures that the barrier doesnt close on a vehicle or person by integrating safety sensors (e.g., infrared, pressure sensors).

2. Key Components of the PCB:

-

Microcontroller or Microprocessor: This is the brain of the PCB, responsible for processing the input signals and controlling the output actions (e.g., opening or closing the boom arm).

-

Relay or Solid-State Switches: These are used to control high-power devices such as the motor or actuator that operates the boom arm.

-

Power Supply Circuit: Converts AC or DC input voltage to the appropriate level to power the controller and other components.

-

Sensor Interface: Connects with various sensors (like vehicle detectors or position sensors) to ensure proper operation.

-

Communication Interface: This may include RS485, Bluetooth, or Wi-Fi modules to integrate with remote access systems or for remote monitoring.

-

LED Indicators: For visual feedback about the system's status (e.g., barrier is open or closed, error indicators).

-

Fuses and Protection Circuits: To protect the PCB and connected devices from electrical surges or short circuits.

3. Features of Boom Barrier Controller PCB:

-

Automatic Operation: The controller can automatically lower or raise the boom arm based on sensors or a pre-set timing sequence.

-

Remote Control Compatibility: Many systems allow for operation via remotes, RFID, or QR codes, and the PCB manages these inputs.

-

Safety Mechanisms: Built-in features to prevent accidents, such as sensors that stop the barrier from closing if an object is detected in its path.

-

Adjustable Timing: The controller can adjust how long the boom remains open or closed depending on user settings.

-

Overload Protection: To prevent motor damage, the controller can stop the boom arms movement if resistance is detected, indicating a potential obstruction.

4. Working Mechanism of a Boom Barrier Controller PCB:

-

Input Received: The controller receives an input signal from a sensor (e.g., vehicle detection) or access system (e.g., a keycard reader or remote).

-

Signal Processing: The microcontroller processes this signal and determines whether to raise or lower the boom arm.

-

Motor Activation: The PCB activates the relay or motor driver to power the motor, which moves the boom arm.

-

Monitoring Feedback: The controller continuously monitors the position of the boom arm, ensuring it is in the correct position.

-

Safety Check: Safety sensors are monitored to ensure no obstruction is present in the path of the boom before closing it.

-

Automatic Timing: The boom arm stays open for the specified time or until the vehicle has cleared, then automatically closes.

5. Types of Boom Barrier Controller PCBs:

-

Basic Controllers: These offer simple control over the boom arm, typically using switches or basic sensors to detect vehicles and control timing.

-

Advanced Controllers: These feature more advanced capabilities, such as integration with remote monitoring systems, data logging, and access control via RFID or biometric authentication.

6. Applications:

-

Parking Lots: Managing the flow of vehicles entering or exiting the lot.

-

Toll Gates: For controlling traffic flow at toll booths.

-

Security Checkpoints: At high-security locations, controlling access for authorized vehicles only.

-

Residential Complexes: Providing controlled access to residents and visitors.

7. Advantages of Using a PCB-Based Controller:

-

Reliability: PCBs are highly reliable and can function in harsh environments.

-

Customization: The controller can be programmed or configured for various barrier functions based on specific needs.

-

Ease of Integration: Can be integrated with various sensor systems and remote access technologies.

-

Compact Size: The PCB is typically small, making it easy to fit into the barrier housing.

-

Cost-Effective: A well-designed PCB can reduce the overall cost of the barrier system by providing efficient control.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry Call Me Free

Call Me Free